Tel

Add

Service hotline

Service hotline

“CAPTEC”brand FLEXPRUF 100-PVDF UV Resistant self adhering/adhesive Exposed Roofing waterproofing membrane is ready to install direct from the factory. It is made out of the binder of thermoplastic polyolefin (TPO) supplemented by flame retardant, light blocking agent, antioxidant, stabilizer and so on. The lower surface of TPO sheet is coated with polymer butyl self adhering/adhesive, which was covered by a release film.

Advantages

Excellent protection against the damage caused by heat, weather elements, and UV rays. Heat-welded seams provide excellent 25 years performance.

Fast to install — up to 60% faster membrane installation than traditional TPO Roofing waterproofing membrane

Saving energy —Reflective white membrane can help reduce building cooling costs.

Easy clean-up — no buckets, rollers, or canisters to dispose of — just the release liner;

Minimal disruption to building occupants — avoid odor associated with solvent-based adhesives. Minimal

disruption to building occupants makes it a good option for use on buildings like schools and hospitals.

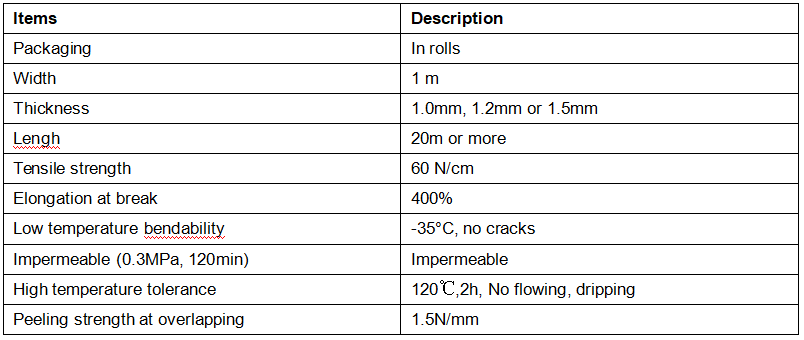

Specification

Application Range

Used for all kinds of roof waterproofing projects for various industrial building, civil building and public building etc.

Application Method of Construction

FLEXPRUF 200-TPO UV Resistant self adhering/adhesive Exposed Roofing waterproofing membrane is ready to install direct from the factory. Review full application instructions for approved substrates and additional application information before use.

Transportation and storage

· During storage and transportation, different types and specifications of products are stacked separately.

· Avoid sun and rain, pay attention to ventilation, and the storage temperature should not be higher than 45°C.

· When stacking flat storage, the stacking height does not exceed five layers, and it is forbidden to have acids, alkalis, oils and have Organic solvent contact.