Tel

Add

Service hotline

Service hotline

“CAPTEC”brand FLEXPRUF 501 Roof Acrylic Acid High Elastic Waterproofing coating is made out of the base of acrylate copolymerization emulsion , together with high quality pigment, filler and the selected multiple-functional auxiliary .This product has exellent elasticity, bonding strength and ultraviolet resistance,mainly used for metal directly exposed roofing waterproof engineering, for other roofings like concrete roofing and bituminous roofing etc.

Advantages

·Exellent mechanical property: High tensile strength, large elongation, and perfect fracture resistance.

·Firm bonding: High bonding strength, can bond base firmly.

·Perfect low temperature flexibility : Flexible at low temperature, no fracture when folded at -30℃ .

·Good aging resistance: outstanding outdoor durability and ultraviolet resistance.

·Corrosion resistance: Highly resistant to acid and alkali, restraining mould and algae growth.

·Breathability: Perfect breathability, no bubbling, non-scale.

·Thermal barrier effect: Light color paint, reflecting most of heat to reduce indoor temperature.

·Good waterproofing effect: compact integrated film coating,durable for long term resistant to water erosion.

·Protective property: exellent weather resistance and ultraviolet resistance, to extend roof service life.

·Environmentally friendly: Water base paint, no organic solvent, no toxin, harmless, friendly to surroundings.

·Convenient construction: Single component, available for usage after open the paint can, cold construction, easy operation

Application Range

Mainly used for waterproof engineering for directly exposed color steel roof, and also used for other roofing system like concrete roofing and bituminous roofing etc.

Installation method

The installation temperature is 5°C ~35°C, the relative humidity is below 85%, and it is raining and snowing

No construction is allowed on windy days above level 5. Please follow the guidance provided by CAPTEC for construction

Instructions are carried out.

· Grassroots treatment: the base layer should be smooth, no floating ash, no oil stain, no rust, no clear water,

Reinforcement of loose fasteners and grinding of rusted parts. It is used for color steel roofing corrosion and damage

When heavy or concrete roofing, the construction must be matched with a primer.

· Detail additional waterproof layer construction: use high-pressure airless spraying, roller coating or brushing

Construction, expansion joints, drainage pipes and lap joints and other detailed nodes to make a reinforcing layer, mining

Take the method of "one cloth and two coatings", embed the reinforced polyester cloth into the paint and add it

Solid treatment, so that the waterproof coating fully soaks the carcass layer, and there must be no wrinkles and warped edges

Elephant.

· Construction of waterproof layer of large-surface coating film: large-surface waterproof coating film should be coated in 2-3 times,

The second pass of construction is carried out after the first pass, and the coating time interval is generally 12h.

The drying time in the low temperature environment should be appropriately extended, and the thickness of each coating film should be 0.5mm.

It should not be too thick at one time, the direction of painting is perpendicular to each other, the painting is even, and the coating should not be missed.

Precautions

· For each millimeter thick film, theoretical coating dosage weight is 2.3 kg/ ㎡~ 2.6kg/ ㎡ .

· When transporting, it should be anti-freezing, prevent sun and rain, squeezing and collision, and keep the packaging complete Good lossless.

· 5 °C ~ 35 °C in a cool and dry place for storage, and avoid exposure and freezing.

· Under normal transportation and storage conditions, the shelf life is 12 months

· After opening the lid and using it, the unused part should be sealed and stored to prevent the paint from being contaminated Dry crusts.

· There may be slight delamination before the opening of the barrel of the paint, and it is made after stirring evenly

No need to add additional water.

· Protective equipment should be worn during construction, such as stained eyes, should be rinsed with water in time,

Tools should be cleaned with tap water immediately after construction.

· Before the coating film is dry, it is forbidden to walk on the waterproof layer, and pay attention to protect it from damage Injury, destruction.

· The quality requirements of the coating film surface: consistent color, no sand hole, no missed coating is allowed,

Bottom-penetrating, powdering, peeling, alkaline, biting, falling, pimple and other phenomena.

· This product should not be mixed with other brands of paint.

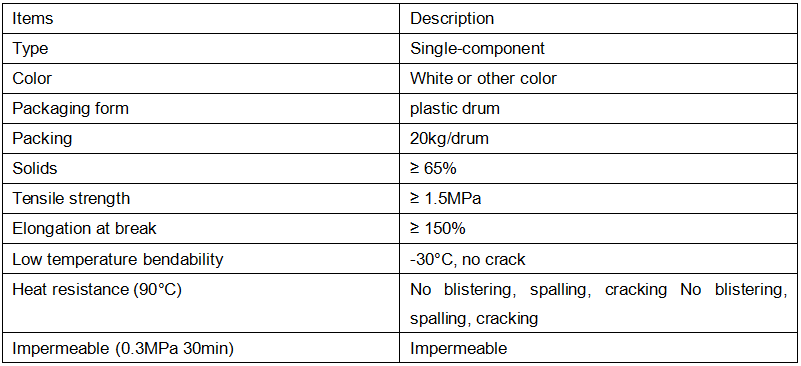

Specifications