Tel

Add

Service hotline

Service hotline

“CAPTEC” brand FLEXPRUF 601 Single-Component Polyurethane Waterproofing Paint is made out of the main materials of isocyanate and polyether polyol, together with various auxiliaries and fillers by polyreaction ,we coat it on the waterproofing base, after chemical reaction of NCO terminal group of polyurethane prepolymer and moisture in air, it forms a jointless , flexible and strong rubber waterproofing film.

Advantages

·Single component, being available after open the paint can, convenient construction.

·High tensile strength, large elongation, good elasticity, perfect low and high temperature resistance, and being adaptive to shrinkage, fracture and deformation of base.

·Strong bonding strength, no need to apply brushing coat of base treating agent on various qualified base surfaces.

·Large single time coating thickness, compact film, no pinhole, no bubble.

·Film is formed by chemical reaction, long term resistance of water erosion, corrosion resistance, mould resistance and fatigue resistance;

·Environmental protection, contains no benzene or coal tar due to usage of high boiling point solvent, adding solvent during construction is unnecessary.

·Cold construction:easy to use.

Application Range

·Adaptive to basement (basement of building, basement parking lot, open-cut subway and passageway).

·Kitchen, bathroom, floor,balcony, non-exposed roof.

·Waterproofing engineering of swimming pool, man-made fountain, water pool and water canal.

·Roof waterproof engineering for parking lot and square .

Reference Dosage

·For each millimeter thick film, coating dosage weight is about 1.4-1.7kg/ ㎡

Application Method

Surface preparation

Surfaces should be dry, stable, clean, smooth, without pockmarks or honeycombs and free from any dusts, oil or loose particles. Cracks and surface irregularities need to be filled by sealants and do additional waterproofing. For smooth and stable surfaces, this step can be skipped. Additional layer

Paint FLEXPRUF 601 as additional layer to enhance at internal and external corners, drain pipes, floor drains or embedded parts.

Application of waterproof coated membrane

Rubber scrapers or spray equipments can be used to paint 2 or 3 times. After fully dry, painting can be repeated. The normal time between each layer is 24 hour. The direction of application layers should be perpendicular to the previous one.

Application of protection layer

After waterproof coated membrane is fully cured and meets the quality requirements, the application of protection layer.could be started

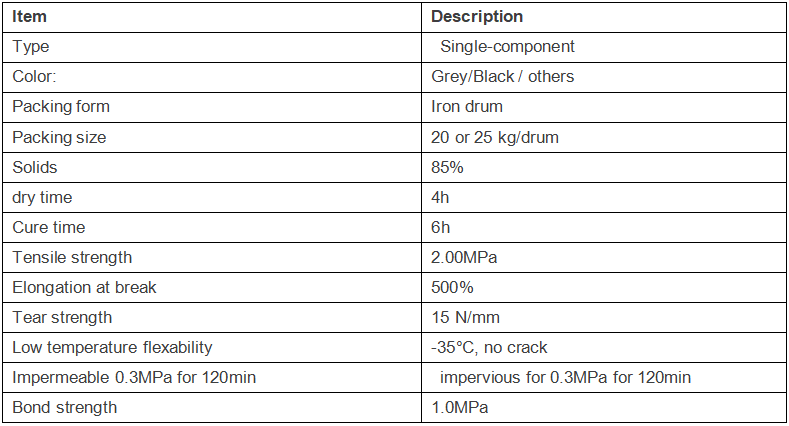

Specification

Packaging

FLEXPRUF 601 is sealed in 20kg or 25kg pails and transported in wooden cases. Each wooden case contains 36 pails of FLEXPRUF 601.

Storage and Transportation

FLEXPRUF 601 material should be stored by sealed pails at dry, well-ventilated places and should be protected from direct sun or rain. The temperature in stored places should not exceed 40° C. Avoid from fire sources. FLEXPRUF 601 is needed to be avoided direct sunshine and rain. Fire sources should be avoided during transportation.

Notice

The application temperature of FLEXPRUF 601 should be above 5℃.

FLEXPRUF 601 should be consumed instantly and can not be diluted with solvent.