Tel

Add

Service hotline

Service hotline2024-08-11

Butyl waterproof tape is specifically designed for waterproofing the seams of daylighting PC boards. Currently, butyl sealing waterproof tape has played a very important role in the sealing and waterproofing engineering of civil structure roofs and metal panel surfaces using supporting materials such as waterproofing membrane bonding, metal profiled sheet bonding, and PC board bonding.

1、 Select specifications and dimensions based on the gap and seam width of the metal plate type or joint area, in accordance with engineering design requirements.

2、 Wipe the joint area of the metal plate clean.

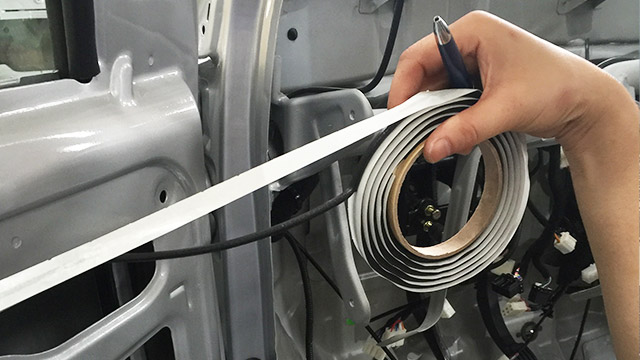

3、 Starting from one end of the metal plate, slowly open the butyl tape along the seam and stick the sealing tape in a straight line to the overlap of the lower metal plate. Then gently press the tape with your hand to firmly bond it to the metal.

4、 Tear off the isolation paper on top of the Hongqing butyl sealing tape, press the metal plate on the upper layer of the interface into the joint, and after bonding, sequentially squeeze the joint to make it firmly bonded and tightly sealed.

5、 Tighten the screws to ensure that the upper and lower bonding surfaces of the sealing tape are tightly bonded.

Regarding the performance and use of butyl sealing waterproof tape!

Waterproof engineering construction requires high-quality and reliable sealing tape. Hongqing butyl sealing tape is made by mixing main raw materials such as butyl rubber and polyisobutene. According to a special production formula, it adopts new patented technology, selects high-quality imported polymer materials, and produces environmentally friendly solvent-free sealing tape through a special process flow.

It has the following advantages:

1、 Excellent mechanical properties: high bonding strength, tensile strength, good elasticity and elongation, can maintain flexibility, strong adaptability to interface deformation and cracking, and can withstand a certain degree of displacement.

2、 Stable chemical properties: excellent waterproof sealing and chemical corrosion resistance, strong resistance to ultraviolet radiation (sunlight), can last for more than 20 years, and does not cure.

3、 Reliable application performance: good low temperature resistance and followability, good dimensional stability, and simple construction operation process, easy to use.